DO I EVEN NEED AN ELECTRIC MOONSHINE STILL CONTROLLER?

I received a call the other day on our Hi Proof Products line. Without mentioning any names. The fellow went on to tell me that he makes and sells stills. He said that he tells all his customers that no controllers are needed to properly distill alcohol. Likewise when talking to other folks about their distilling there also seems to be a lot of confusion around why you even need a heat controller in the first place and how and why you can use it to control your distillation temperature. Simply put you can’t do without a controller and now I will give you a more in depth explanation as to why you need to be able to control the heating process.

BOILER TEMPERATURE VERSUS THE SPEED OF VAPORIZATION/BOIL

So lets start at the beginning. The whole idea in distilling is to boil your mash to take advantage of the fact that alcohol boils at a lower temperature than water and a lot of other nasty compounds that you don’t want in your final distillate resulting in something that has a higher alcohol by volume (ABV). The temperature that the mash will boil at depends entirely upon the ABV of the mash that is boiling, and based on this ABV will boil somewhere between the boiling point of ethanol which is 173F and water which is 212F. The higher your washes ABV is, the closer your temperature will be to 173F. And the lower your ABV is the closer your temperature will be to 212F. And to further complicate things, as you start to boil the ethanol out of your wash the ABV of the wash will decrease so the temperature that it boils at will also change.

This is very important so I'll say it again. The ABV is the only thing that will affect the temperature that your wash is boiling at which should be the same as the vapors in the head of your boiler. Turning up the heat to your boiler will not increase this temperature unless of course your mash hasnt’t started boiling yet. What turning up the heat will do is increase the rate of boil at which the wash is being vaporized. Making a liquid change its phase from liquid to steam or into a gas takes lots of energy.

Think about the way boiling a pot of water on the stove works. Tap water boils at 212F. Once it reaches that temperature it starts boiling but the temperature does not go above 212F. True turning up the heat does make it boil faster which increases the rate of vaporization and turning the heat down makes it boil slower but it does not change the boiling temperature. Hope I haven't lost you yet because it gets better.

WHY IT'S IMPORTANT THAT YOU CONTROL THE RATE OF VAPORIZATION/BOIL

This leads me into why you NEED to be able to control your heat input. You need to be able to control the rate at which the vapors are traveling up your column or into your still head. The reasoning behind this is slightly different for a pot still vs. a reflux still.

Controlling the rate of vaporization is important for a pot still so that you do not end up pumping vapors through so quickly that the condenser cannot condense all of the vapors back to into a liquid distillate. When this happens you end up with vapor blowing out of the end of your still which is not good and is a waste of perfectly good alcohol! The only exception to not needing to control the rate of boil is for a heat source that physically cannot put out too much heat for your particular condenser. For example, a 1500 watt heating element can be used without any controller if and only if your condenser is capable of condensing all of the vapors that a 1500 watt element will generate as long as the water pumped through the condenser is cold enough. Make sense?

Controlling the rate of vaporization is important for a reflux still so that you can get the right balance of vapors travelling up the still vs. reflux travelling back down (equalization of the column) If you plug a 5500 watt heating element into a reflux still a couple things would most likely happen. First you would run into the same problem as the pot still where the condenser would not be able to handle all the vapor thrown at it and it would blow out the end of your still. Second the vapor would be travelling up the still tower so quickly that it would basically blow the vapor up the column. When there is no reflux in the column you don’t get the vapor exchange in all the packing of your column and usually the blown vapor will pool on top of your packing until it reaches the lyne arm at which point the clear distillate will surge out every once in a while. The old boys used to call this condition puking. So long story short YES you need to be able to adjust the heat down to a level that will work with your still setup.

WAYS TO CONTROL YOUR HEAT SOURCE

Most beginners start with a propane burner setup because it is cheaper than the electric counterpart and that is just fine. However the major problem we find with the great majority of the propane burners offered today is that they have trouble going low enough to get a slow steady trickle of distillate out of your column. They have a built in venturi to help suck in fresh air for combustion but when you turn the still down this low that ceases to function properly and the flame will burn yellow instead of blue and leave all kinds of soot on the bottom of your boiler due to the lack of oxygen. Plus a imbalance of air/fuel mixture is the most likely cause of producing deadly carbon monoxide gas which is not something that you want to be working around period. I'm a loooong time HVAC guy and I have seen quite a few gas furnace burners that were actually burning inside the venturi tube instead of at the burner head because somebody that didn't know what they were doing messed with the pressure regulator a very unsafe condition.

When it comes to electric heat controllers there are several different control methods out there offered. The first to cover are thermostat controllers since we most often see these misused. Thermostats are basically just temperature controlled relays that are 100% on if they are below the set temperature or 100% off if they are above the set temperature. And as we mentioned before the ABV in the wash controls the temperature of the boiling wash not your heat source. So this simply will not work to try and control your heat output. Even if you did manage to tune it to the exact temperature that the wash will boil at it will cycle on and off causing surges of distillate which will wreak havoc on the way a reflux still operates. Plus as the ethanol gets boiled off the temperature needed to cause the wash to boil will rise so your heat source will stay 100% off and the still will just stop distilling anything. The main thing that thermostat controllers are good for is getting the still to a pre-boil condition and holding it there until you return from your lunch break to do the run or shutting the still off once you get to a higher temperature that should mean you are into your tails.

PID controllers are basically glorified programmable thermostats. As is the case with thermostat controls they are not ideal. Some do have options to modulate heat by cycling on and off more frequently however this also cycles your solid state relay (SSR) on and off much more frequently putting additional stress on it. But on the plus side they are somewhat programmable.

The last controller type that we need to cover are phase-angle type controllers. These controllers similar to the ones that we offer are quite sophisticated in nature. They work by only allowing a certain portion of the electricity’s wavelength through based upon the resistance provided through the solid state variable resistor. Since we have 60 Hz power, that is effectively cycling the heating element on and off 60 times per second without actually firing the electronics on and off 60 times per second. This gives you a much smoother flow of energy into your boiler, which then boils your wash steadily. It is important to note however that as you boil the ethanol out of your wash it takes more energy to produce the same column of vapor since the water content is increased and water takes more energy to vaporize than ethanol would. So you will still need to turn your heat source up slightly every once in a while throughout the course of the run. This is no big deal and can be done with the push of a button on our controllers. Besides you should never run any still unattended.

So I hope that this clears a lot of the questions and hype about control up for you. Happy distilling!

SOME ADDITIONAL INFORMATION RELATING TO HEATERS

Modern moonshine still boilers for the most part use the same electric immersion heaters that are used in residential and light commercial electric water heaters. They are available most commonly rated 110 & 220 volt and come in various watt ratings.

They are deemed much safer to use than say a propane fired heater because obviously there is no open flame you need to worry about when working near flammable alcohol.

WHAT DO MOONSHINE STILL IMMERSION HEATER WATT RATINGS MEAN?

Think about the difference between 40 watt and 100 watt light bulb.

higher the watts, the hotter the light bulb, and the higher output of total energy

So a 5500 watt element gets hotter than 3500 watt element, and a 5500 watt element uses more total energy.

So large boilers might use a 5500 watt element or in some cases 2 elements since they heat more liquid. While a small boiler holding less liquid might use a 120 volt 1500 watt element.

WHAT ARE THE DIFFERENCES IN POWERING A HEATER WITH 110 VOLTS AS OPPOSED TO 220 VOLTS?

All single phase circuits require 2 wires to complete the circuit

120 volt heaters take 1 hot wire and 1 neutral wire

240 volt heaters takes 2 hot wires

No neutral wire is needed to complete a 220 volt circuit, but for safety reasons it is highly recommended.

240 volts can deliver energy more efficiently than 120 volts

240 volt immersion heaters are more efficient

SO WHAT'S ALL THE BUZZ ABOUT AMPS ANYWAY?

Amps is a measure of the size wire needed to supply energy (amps) to heaters

For example, a 5500 watt element needs heavier wire than a 40 Watt light bulb

The complete circuit is made up of a circuit breaker, wire, and electrical connectors needed to handle the energy (amps) required.

WHEN IT COMES TO ELEMENTS DON'T DO THIS

The quickest way I know of to destroy your immersion element short of beating it with a sledge-hammer is to run it dry. The element should ALWAYS be covered completely in liquid when it is powered up. If you seem to start going through more than a few immersion elements then I would suggest switching to a low density element as well.

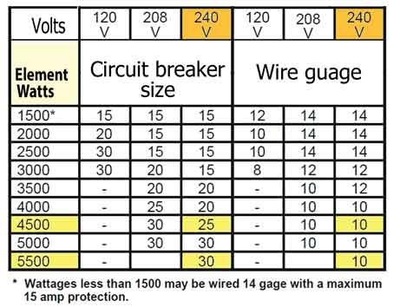

HOW TO DETERMINE WHAT SIZE BREAKER YOU'LL NEED FOR A PARTICULAR MOONSHINE STILL HEATER

Formula:

Volts x amps = watts

Same as P = VI ... Power (watts) = V (volts) x I (amps)

Example: 4500 watt element, 240 volt heater circuit, how many amps are required?

Amps = 4500 watt ÷ 240 volt = 18.75 amp draw.

BOILER TEMPERATURE VERSUS THE SPEED OF VAPORIZATION/BOIL

So lets start at the beginning. The whole idea in distilling is to boil your mash to take advantage of the fact that alcohol boils at a lower temperature than water and a lot of other nasty compounds that you don’t want in your final distillate resulting in something that has a higher alcohol by volume (ABV). The temperature that the mash will boil at depends entirely upon the ABV of the mash that is boiling, and based on this ABV will boil somewhere between the boiling point of ethanol which is 173F and water which is 212F. The higher your washes ABV is, the closer your temperature will be to 173F. And the lower your ABV is the closer your temperature will be to 212F. And to further complicate things, as you start to boil the ethanol out of your wash the ABV of the wash will decrease so the temperature that it boils at will also change.

This is very important so I'll say it again. The ABV is the only thing that will affect the temperature that your wash is boiling at which should be the same as the vapors in the head of your boiler. Turning up the heat to your boiler will not increase this temperature unless of course your mash hasnt’t started boiling yet. What turning up the heat will do is increase the rate of boil at which the wash is being vaporized. Making a liquid change its phase from liquid to steam or into a gas takes lots of energy.

Think about the way boiling a pot of water on the stove works. Tap water boils at 212F. Once it reaches that temperature it starts boiling but the temperature does not go above 212F. True turning up the heat does make it boil faster which increases the rate of vaporization and turning the heat down makes it boil slower but it does not change the boiling temperature. Hope I haven't lost you yet because it gets better.

WHY IT'S IMPORTANT THAT YOU CONTROL THE RATE OF VAPORIZATION/BOIL

This leads me into why you NEED to be able to control your heat input. You need to be able to control the rate at which the vapors are traveling up your column or into your still head. The reasoning behind this is slightly different for a pot still vs. a reflux still.

Controlling the rate of vaporization is important for a pot still so that you do not end up pumping vapors through so quickly that the condenser cannot condense all of the vapors back to into a liquid distillate. When this happens you end up with vapor blowing out of the end of your still which is not good and is a waste of perfectly good alcohol! The only exception to not needing to control the rate of boil is for a heat source that physically cannot put out too much heat for your particular condenser. For example, a 1500 watt heating element can be used without any controller if and only if your condenser is capable of condensing all of the vapors that a 1500 watt element will generate as long as the water pumped through the condenser is cold enough. Make sense?

Controlling the rate of vaporization is important for a reflux still so that you can get the right balance of vapors travelling up the still vs. reflux travelling back down (equalization of the column) If you plug a 5500 watt heating element into a reflux still a couple things would most likely happen. First you would run into the same problem as the pot still where the condenser would not be able to handle all the vapor thrown at it and it would blow out the end of your still. Second the vapor would be travelling up the still tower so quickly that it would basically blow the vapor up the column. When there is no reflux in the column you don’t get the vapor exchange in all the packing of your column and usually the blown vapor will pool on top of your packing until it reaches the lyne arm at which point the clear distillate will surge out every once in a while. The old boys used to call this condition puking. So long story short YES you need to be able to adjust the heat down to a level that will work with your still setup.

WAYS TO CONTROL YOUR HEAT SOURCE

Most beginners start with a propane burner setup because it is cheaper than the electric counterpart and that is just fine. However the major problem we find with the great majority of the propane burners offered today is that they have trouble going low enough to get a slow steady trickle of distillate out of your column. They have a built in venturi to help suck in fresh air for combustion but when you turn the still down this low that ceases to function properly and the flame will burn yellow instead of blue and leave all kinds of soot on the bottom of your boiler due to the lack of oxygen. Plus a imbalance of air/fuel mixture is the most likely cause of producing deadly carbon monoxide gas which is not something that you want to be working around period. I'm a loooong time HVAC guy and I have seen quite a few gas furnace burners that were actually burning inside the venturi tube instead of at the burner head because somebody that didn't know what they were doing messed with the pressure regulator a very unsafe condition.

When it comes to electric heat controllers there are several different control methods out there offered. The first to cover are thermostat controllers since we most often see these misused. Thermostats are basically just temperature controlled relays that are 100% on if they are below the set temperature or 100% off if they are above the set temperature. And as we mentioned before the ABV in the wash controls the temperature of the boiling wash not your heat source. So this simply will not work to try and control your heat output. Even if you did manage to tune it to the exact temperature that the wash will boil at it will cycle on and off causing surges of distillate which will wreak havoc on the way a reflux still operates. Plus as the ethanol gets boiled off the temperature needed to cause the wash to boil will rise so your heat source will stay 100% off and the still will just stop distilling anything. The main thing that thermostat controllers are good for is getting the still to a pre-boil condition and holding it there until you return from your lunch break to do the run or shutting the still off once you get to a higher temperature that should mean you are into your tails.

PID controllers are basically glorified programmable thermostats. As is the case with thermostat controls they are not ideal. Some do have options to modulate heat by cycling on and off more frequently however this also cycles your solid state relay (SSR) on and off much more frequently putting additional stress on it. But on the plus side they are somewhat programmable.

The last controller type that we need to cover are phase-angle type controllers. These controllers similar to the ones that we offer are quite sophisticated in nature. They work by only allowing a certain portion of the electricity’s wavelength through based upon the resistance provided through the solid state variable resistor. Since we have 60 Hz power, that is effectively cycling the heating element on and off 60 times per second without actually firing the electronics on and off 60 times per second. This gives you a much smoother flow of energy into your boiler, which then boils your wash steadily. It is important to note however that as you boil the ethanol out of your wash it takes more energy to produce the same column of vapor since the water content is increased and water takes more energy to vaporize than ethanol would. So you will still need to turn your heat source up slightly every once in a while throughout the course of the run. This is no big deal and can be done with the push of a button on our controllers. Besides you should never run any still unattended.

So I hope that this clears a lot of the questions and hype about control up for you. Happy distilling!

SOME ADDITIONAL INFORMATION RELATING TO HEATERS

Modern moonshine still boilers for the most part use the same electric immersion heaters that are used in residential and light commercial electric water heaters. They are available most commonly rated 110 & 220 volt and come in various watt ratings.

They are deemed much safer to use than say a propane fired heater because obviously there is no open flame you need to worry about when working near flammable alcohol.

WHAT DO MOONSHINE STILL IMMERSION HEATER WATT RATINGS MEAN?

Think about the difference between 40 watt and 100 watt light bulb.

higher the watts, the hotter the light bulb, and the higher output of total energy

So a 5500 watt element gets hotter than 3500 watt element, and a 5500 watt element uses more total energy.

So large boilers might use a 5500 watt element or in some cases 2 elements since they heat more liquid. While a small boiler holding less liquid might use a 120 volt 1500 watt element.

WHAT ARE THE DIFFERENCES IN POWERING A HEATER WITH 110 VOLTS AS OPPOSED TO 220 VOLTS?

All single phase circuits require 2 wires to complete the circuit

120 volt heaters take 1 hot wire and 1 neutral wire

240 volt heaters takes 2 hot wires

No neutral wire is needed to complete a 220 volt circuit, but for safety reasons it is highly recommended.

240 volts can deliver energy more efficiently than 120 volts

240 volt immersion heaters are more efficient

SO WHAT'S ALL THE BUZZ ABOUT AMPS ANYWAY?

Amps is a measure of the size wire needed to supply energy (amps) to heaters

For example, a 5500 watt element needs heavier wire than a 40 Watt light bulb

The complete circuit is made up of a circuit breaker, wire, and electrical connectors needed to handle the energy (amps) required.

WHEN IT COMES TO ELEMENTS DON'T DO THIS

The quickest way I know of to destroy your immersion element short of beating it with a sledge-hammer is to run it dry. The element should ALWAYS be covered completely in liquid when it is powered up. If you seem to start going through more than a few immersion elements then I would suggest switching to a low density element as well.

HOW TO DETERMINE WHAT SIZE BREAKER YOU'LL NEED FOR A PARTICULAR MOONSHINE STILL HEATER

Formula:

Volts x amps = watts

Same as P = VI ... Power (watts) = V (volts) x I (amps)

Example: 4500 watt element, 240 volt heater circuit, how many amps are required?

Amps = 4500 watt ÷ 240 volt = 18.75 amp draw.

HOW ELECTRIC MOONSHINE CONTROLLERS WORK WITH DIFFERENT INPUT VOLTAGES

The long and short of it is that as input voltage drops your immersion heaters ability to produce heat decreases. In the case of a variable heater this is good since it enables us to dial the heat from zero to 100%, and in the case of a still boiler temperature control makes the difference between a good batch and a failed batch of moonshine.

Example: A 5500 watt rated moonshine still immersion heater drops to a low 4125 watts when powered with 208 volts instead of 240 volts. Why? Electric elements are like light bulbs... that is when power drops, then light bulbs dim, and produce less wattage output. Same with moonshine still immersion elements: when voltage drops, the element is less hot and wattage output is lower

QUICKER HEATING OF MOONSHINE STILL BOILER

In the case of smaller moonshine still boilers some guys like to install a immersion heater that is overkill. In this way they can quickly bring the boiler up to temperature then dial the heat down using a digital controller to do the final brewing.

Others add a second, third, or even fourth immersion element to act as "afterburners" of sorts bringing the boiler temperature up very quickly. then once final working temperature is reached one or more elements are switched off and the brewing process is completed using fewer elements throttled by a digital controller.

As a side note no one but Hi Proof Products does more testing and research on their controllers. Plus we are constantly striving for improvement. We have built and sent out hundreds of controllers and folks love them. They are a proven design, are very easy to operate, and they work flawlessly. We have built controllers for mikro-distilleries as well as home-brewers and the guys and gals that have purchased them give them two thumbs up. We are sure you will too.

Whichever method you choose to use rest assured that Hi Proof Products offers state of the art digital controllers in our on-line store like the one shown below. And take note that if you need a particular controller such as a single 5500 watt, double 11,000 watt, triple 16,500 watt, or quad 22,000 watt controller just send us an email, fill out our contact page, or give us a call direct at 330-752-3767 and let's discuss your needs. We'll be more than happy to help you in any way that we can.

The long and short of it is that as input voltage drops your immersion heaters ability to produce heat decreases. In the case of a variable heater this is good since it enables us to dial the heat from zero to 100%, and in the case of a still boiler temperature control makes the difference between a good batch and a failed batch of moonshine.

Example: A 5500 watt rated moonshine still immersion heater drops to a low 4125 watts when powered with 208 volts instead of 240 volts. Why? Electric elements are like light bulbs... that is when power drops, then light bulbs dim, and produce less wattage output. Same with moonshine still immersion elements: when voltage drops, the element is less hot and wattage output is lower

QUICKER HEATING OF MOONSHINE STILL BOILER

In the case of smaller moonshine still boilers some guys like to install a immersion heater that is overkill. In this way they can quickly bring the boiler up to temperature then dial the heat down using a digital controller to do the final brewing.

Others add a second, third, or even fourth immersion element to act as "afterburners" of sorts bringing the boiler temperature up very quickly. then once final working temperature is reached one or more elements are switched off and the brewing process is completed using fewer elements throttled by a digital controller.

As a side note no one but Hi Proof Products does more testing and research on their controllers. Plus we are constantly striving for improvement. We have built and sent out hundreds of controllers and folks love them. They are a proven design, are very easy to operate, and they work flawlessly. We have built controllers for mikro-distilleries as well as home-brewers and the guys and gals that have purchased them give them two thumbs up. We are sure you will too.

Whichever method you choose to use rest assured that Hi Proof Products offers state of the art digital controllers in our on-line store like the one shown below. And take note that if you need a particular controller such as a single 5500 watt, double 11,000 watt, triple 16,500 watt, or quad 22,000 watt controller just send us an email, fill out our contact page, or give us a call direct at 330-752-3767 and let's discuss your needs. We'll be more than happy to help you in any way that we can.